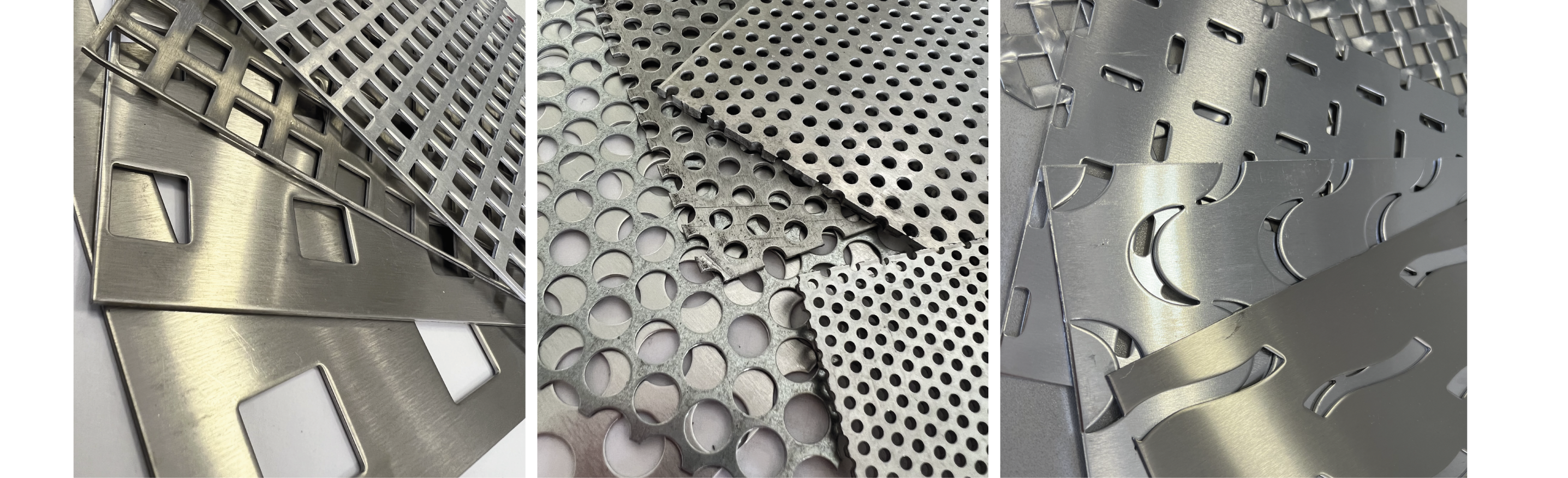

PERFORATED METAL

Usually, for technical reasons, the production of metal sheets is made by blanking.

A set, more or less long, is posed on the top of the machinery, and, on the bottom part there is the matrix. The metal pass between these two parts and advanced by a fixed and regular step, with each stroke, in order to obtain the perforation.

The most common types of holes are round, square, oblong and hexagonal, but, changing the set and the matrix of the machinery, you can get any type and shape of hole.

STANDARD METAL SHEETS

The standard metal sheets are made in the industries with big machinery.

This type of metal sheet allow our workshop to get in the warehouse a big range of types, holes and dimension of sheets, that can satisfy any tipe of requise. Anyway, the sizes of the sheets can be modified and resized in a second moment in relation with the needs of the clients.

Standard sizes: 1000×2000 mm / 1250×2500 mm / 1500×3000 mm

Standard thicknesses: from 0,8 to 10 mm

Type of metals: INOX steel (AISI 304 / 316 / 430), aluminium, raw steel (iron), galvanized steel, corten

CUSTOMED METAL SHEETS

These type of metal sheets are made with a smaller machinary in our workshop. In this way we decide which type of shape, size and thickness according to the project and the needs of the client. In relation of the result that you want to get we can make build some different types of moduls.

The costumes metal sheets are made starting from the client requise or idea. So, the features of the metal sheets can be different according to the different projects and needs.

Materials that we work with: INOX steel (AISI 304 / 316 / 430), aluminium, raw steel (iron), galvanized steel, corten

ADDITIONAL PROCESSING

-Shearing

-Printing

-Calandering

-Bending

-Deep-drawing

-Welding

-Assembly

-Sating finishing

-Polishing

-Coating

-Galvanizing

-Anodizing

APPLICATIONS

The perfored metal is mostly used in the industrial enviroments and now is spreading in the residential design. It can be used for structural applications, but also in a decorative way in the architecture field, like in the surfaces, stairs and protection sheets.

The perforated metal sheets can be used to stop or adjust the passage of lights and, anyway allow the airflow. These can also be used to get more privacy in the open spaces.

Them are perfect to attenuate the sounds and prevent echoes in the closed spaces.

This type of metal sheet can be apllied also on the outside, on the stairs, on the walkways, on the benches and anywhere the water must drain if it starts to rain.

The perfored metal can be used also for little design elements, like lamps, object holders, vase holders, chairs, tables and lots of other types of items.