CLEWED METAL

Saying "clewed metal" it mind a metal sheet on which are pressed, with the embossing technique, some different raised shapes, related to the use that are made for.

During the embossing process the metal sheet is subjected to a heat source and, then, to the pressure applied by the different matrices on the roll.

TYPES OF CLEWED METALS

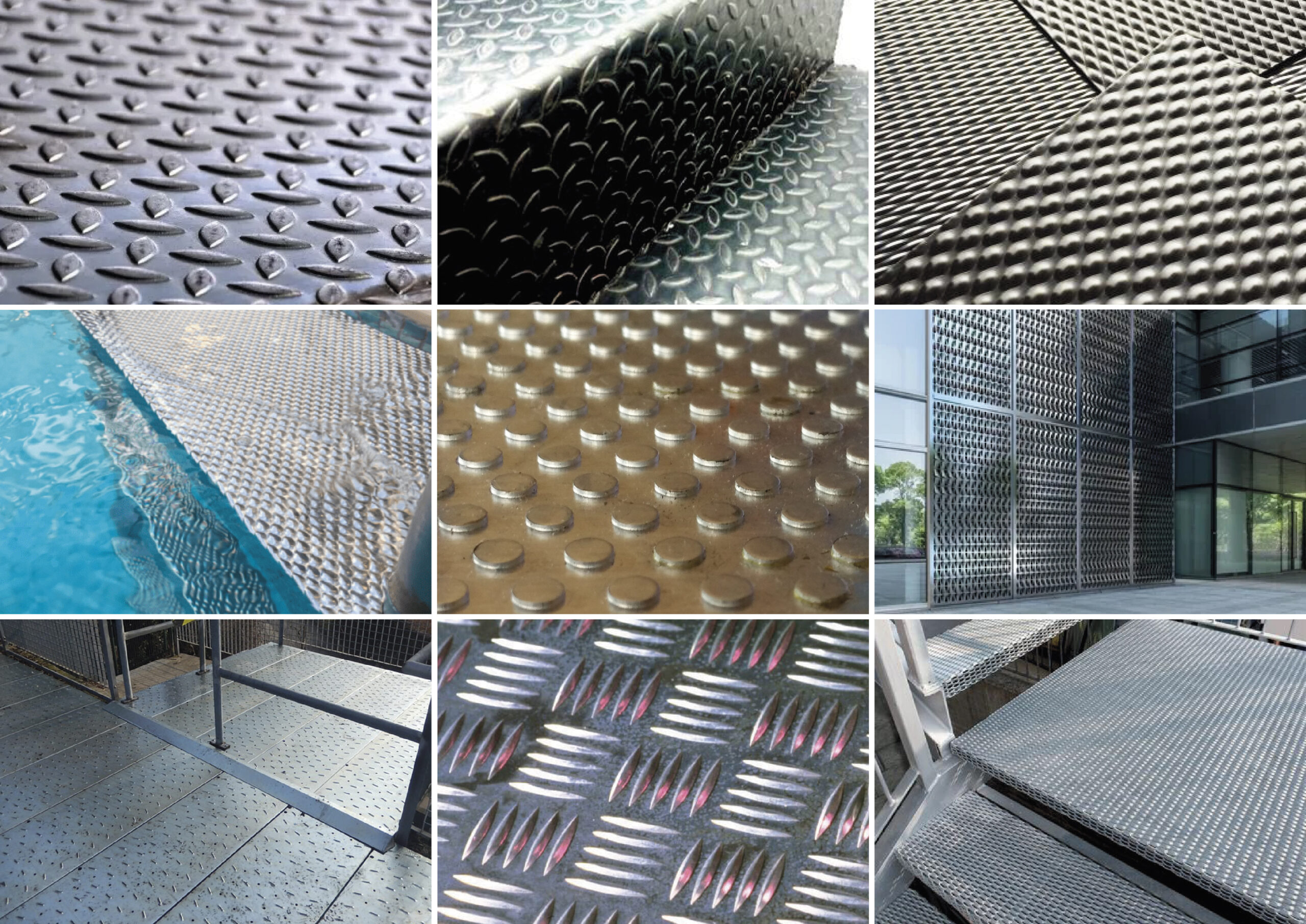

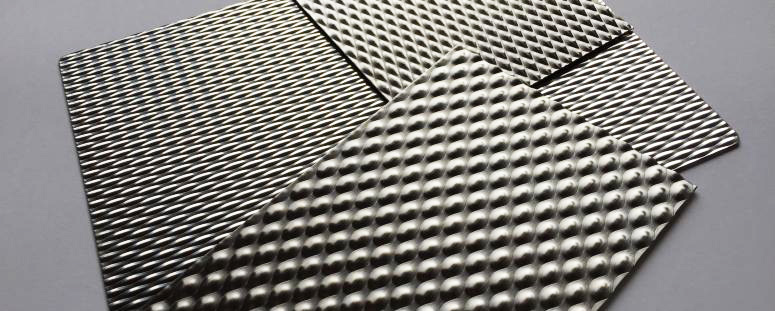

The most common and used types of embrossing are: round, rectangle, rhombus and almond-shaped. Starting from the needs and the future use of the metal sheets, the type of clew can change.

Standard sizes: 1000×2000 mm / 1250×2500 mm / 1500×3000 mm

Standard thicknesses: from 0,8 to 10 mm

Type of metals: INOX steel (AISI 304 / 316 / 430), aluminium, raw steel (iron), galvanized steel

ADDITIONAL PROCESSING

-Shearing

-Printing

-Calandering

-Bending

-Deep-drawing

-Welding

-Assembly

-Sating finishing

-Polishing

-Coating

-Galvanizing

-Anodizing

APPLICATIONS

The most common application fields of clewed metal are construction, to cover the walkways, stairs and runway and for make the walls stronger and to cover the vertical surfaces.

These types of metal sheets, thanks their non-slip effect, are so spread also in the transport segment.

So, the clewed metal sheets are used and applied where the estetical needs must be combined with functional affectiveness, like in the swimmingpool and in the shipyards.